HARDWOOD FLOORING ACCLIMATION

As you purchase your new Old World Timber reclaimed wood floors and/or wall paneling, there are a few things you need to know about getting your wood acclimated. Wood is hygroscopic, meaning it is a material that absorbs moisture based upon the environment it ends up in. Therefore, the wood may arrive at your location with a moisture content (MC) that is different than what is required for installation. So, in order for your reclaimed floors or wall paneling to look their best and not become damaged, you will need to allow the wood to acclimate to the surrounding environment. Failure to properly acclimate the wood could result in cupping or warping in the wood from excessive shrinkage or expansion (wet air expands wood, dry air shrinks wood). This could result in gaps and splits before or after installation, which could all lead to aesthetic and structural damage.

The wood acclimation tips below are based on guidelines from the National Wood Flooring Association (NWFA).

Quick Pro Tips

- Tip #1: Depending on your region, allow the wood to acclimate between 3-7 days.

- Tip #2: Break the flooring bundles into small groupings to improve airflow.

- Tip #3: Turn on all HVAC or air systems while the wood acclimates.

- Tip #4: Follow the manufacturer’s recommendations in order to keep your warranty in effect.

A checklist of what to do:

- Step One: consult with a local licensed professional installer before installing the flooring or paneling material.

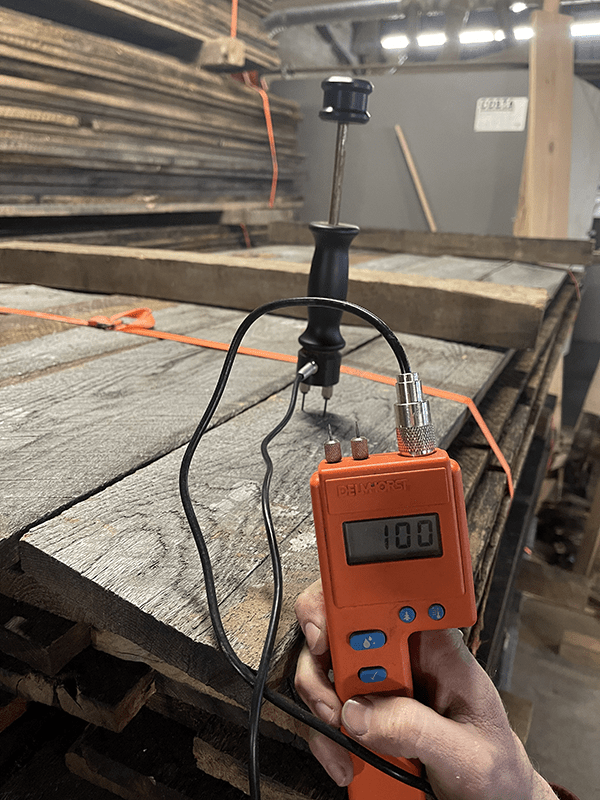

- Step Two: Once you receive your Old World Timber reclaimed wood order, you should take moisture readings using a moisture meter to establish the moisture content (MC). Then, for each bundle, visually inspect the boards for defects.

- Step Three: When preparing to receive your reclaimed flooring or wall paneling, remember to check the seasonal variation of wood moisture content for YOUR specific geographical region by consulting with the National Wood Flooring Association. (Insert regional charts here). If you will be installing in an extreme environment, you will need to increase the acclimation time for the wood to reach moisture equilibrium. Again, speak with a local flooring installation expert.

- Step Four: You will need to properly store your Old World Timber order. Both flooring and wall paneling need to be stored in a clean and dry location with the product still properly wrapped, even if it is only for a short time. All products should be stored on a solid, flat surface that has proper support. We highly recommend spacing out the bundles of flooring or paneling so that proper air flow can take place. This will also speed up the acclimation process. DO NOT store your reclaimed wood product at the job site under uncontrolled environmental conditions. Ensure the wood is stored in an enclosed building. Keep in mind that you can’t store your wood flooring or wall paneling in a garage or outside on a deck.

- Step Five: Check the moisture content (MC) upon delivery or have a local professional check it for you. Immediately upon receiving your wood, check the moisture content using a moisture meter. This will help you establish a baseline for the desired level of acclimation. For best accuracy, check the moisture content of multiple boards; to be extra safe, you will want to check 40 boards for every 1,000 square feet of flooring. Next, you’ll need to calculate the optimal moisture content. To start, determine the anticipated seasonal change in wood moisture content (MC) for your location. Check these guides: Moisture Content by Region-US and Moisture Content by Region-Canada. Simply divide the low season and high season moisture content. Under unique circumstances, you will not need to acclimate the wood if the wood flooring is delivered and recorded at the baseline moisture content for your geographical location and if correct relative humidity conditions are kept. However, if the moisture content of the wood is considerably outside of the desired range of moisture content, it could be extremely hard to acclimate the wood properly. Under these conditions, excessive cupping, bowing, and shrinkage of the wood may appear.

- Step Six: Ensure the long-term environmental systems are running before installation. For example, make certain your HVAC system is running at least 5 days prior to installation at the proper settings for the desired temperature and humidity. This allows the humidity in the room to stabilize where your new Old World Timber floors or wall paneling will soon be living. The relative humidity in the space should be between 30 and 50 percent year round for optimal performance, and the temperature should be between 60 and 80 degrees Fahrenheit. Just like humans, wood reacts best under an ideal range of temperatures and relative humidity. If the humidity or temperature in your space is out of spec, postpone your installation and speak with a local professional. Failing to do so may cause the room to have an improper moisture content that will cause failure. Proper conditions must be maintained over the life of the flooring or wall paneling. There are geographic exceptions to these recommendations, so certainly ask a flooring professional and check the product specifications.

*All these are only guidelines and should be complimented with the expertise and guidance of the National Wood Flooring Association (NWFA) as well as your local professional and expert flooring and wall paneling installer. For more information, please consult a licensed professional or consult with the National Wood Flooring Association (NWFA) prior to installation.

Hardwood Flooring Acclimation Frequently asked questions

Hardwood floors need time to adjust to their new environment before installation. If not, your floors can become cupped or warped within a few weeks of installation. Before you install wood flooring, it does require time to adapt to your area.

It is important to allow oak hardwood flooring to acclimate properly before installation. We advise allowing at least 2 full weeks for the wood flooring to acclimatize properly for 10″ solid oak boards, but expect it to take longer in some cases. Additionally, the hardwood flooring and plywood or T&G subfloor must fall within the allowed range in order for acclimation to be successful.

If wood flooring is not acclimated, it can lead to problems like cupping, warping, and gapping. This is because the wood will expand and contract as the temperature and humidity levels change, causing the boards to become misshapen. This can make your floors look unsightly and can also be dangerous if the boards become loose. To avoid these problems, it is important to acclimate your hardwood floors before installation. This simply means allowing the boards to adjust to the temperature and humidity of their new surroundings for a period of time (usually around 48 hours).

Prefinished hardwood flooring needs to acclimate for a minimum of three days in the installation environment. This is to ensure that the material adapts to the humidity and temperature levels of the area, preventing any issues with the flooring later on. After the three days have passed, you can then proceed with installing the hardwood flooring.

Yes, the subfloor needs to be dry, level, and free of any defects in order to ensure a successful installation. Proper acclimation is required to adjust the moisture content of the subfloor to the surrounding environment. Without proper acclimation, the subfloor may warp or cup.