A Nation Of Lumber

It is said that before the boom of the logging industry in America a squirrel could have climbed a tree in Maine and jumped from tree to tree to eastern Texas without ever touching the ground. That’s how plentiful and majestic the American forestry used to be. Full of original slow growth trees that likely resembled the canopy of the Amazon rain forest more than what we see now in the Appalachian or Smokey Mountains.

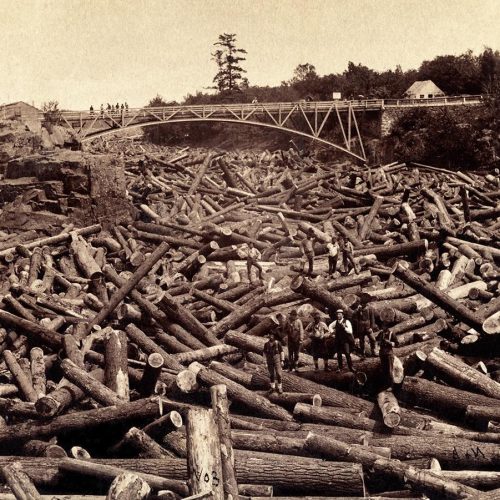

The history of the lumber industry in the US spans from the precolonial period and American development into the twenty-first century (1). The industry expanded rapidly from the Atlantic side all the way to the Pacific as Americans logged their way across the country. Many grew rich in the 1800s from timber harvesting and many towns were made famous solely from their logging dominance such as Bangor, Maine, The Lumber Capital of the World. During the mid 1830s Bangor become the world’s largest lumber shipping port and would move over 8.7 billion board feet of timber (2). No single individual ever became as wealthy as the “Timber King Of The Northwest” Friedrich Weyerhäuser who owned over 2 million acres of pine forest by the time he died in 1914. He could arguable still be considered the eighth richest American of all time (3). Although the pacific northwest was producing 30 percent of the nation’s lumber (4), by the end of the 19th century the great lakes region would dominate logging with Michigan producing more lumber than any other state (5). Still today sunken logs can be found that sank to the bottom of rivers like the Ohio and Mississippi during this timber boom period as loggers would float their treasure down river to different mill towns.

The "Timber" Land

In the early nineteenth century, Western New York was heavily forested, with as much as 100,000 board feet of timber per acre in upland areas like Chautauqua county (6). Southwestern New York was rich in different valuable northern hardwoods like Maple, Oak, Beech, Birch and Chestnut. The County was covered with dense pine forests (7).

Timber was the only resource Chautauqua County possessed that could bear the transportation costs to urban markets so soft pine woods were cut into boards piled into rafts and floated down the Allegheny and Ohio rivers to Pittsburgh and Cincinnati (8).

Besides construction and other development applications, these hardwoods were also burned and their ashes were used to make potash (9). Ten acres of hardwood land yielded up a ton of potash, worth as much as $200 (10). The potash was shipped to New York and Pittsburgh, where it was used as an ingredient in the manufacturing of soap, glass, baking powder and gun powder (11).

Feeding The Appetite

As the nation’s appetite for fuelwood pushed the edge of the forest further and further away from the city the transportation costs rose (12). In the 18th century New York faced frequent shortages and high prices forcing the population to import timber from as far away as Michigan, Wisconsin and even Minnesota (13). Despite the new industrial technologies, lumber prices rose but the city’s rapidly expanding economy easily absorbed the price increases and rising prices were not enough to slow the pace of building construction (14).

The Foil

Steam and steel, the 19th century’s major industrial technologies enabled the lumber industry to keep up with rising demand, albeit at a rising cost (15). Despite the dangers inherent in the use of wood as a building material in 1912 there were still over 82,000 buildings of ordinary brick and wood constructions standing on the island and nearly 7000 wood-frame buildings (16). These constructions continued to dominate in 1914 and only 43 percent of the 426 new building plans were fireproof structures, the remaining 57 percent were still to be ordinary constructions with their high wood content (17).

Today, in the 21st century, we now have the opportunity as well as the responsibility to not allow these centuries-old timbers to go to waste either from rot and decay or from building deconstruction. Instead of paying landfills to dump these beams, planks and timbers and watch the history they tell disappear, many companies such as ours are repurposing these planks into interior and exterior design products that can continue to last for many more generations to come. And although no squirrels will be able to make a cross country trip without touching the soil, by repurposing old-growth timbers we help preserve the trees that do remain. And that’s something everyone can celebrate.

(1) (2) (4) (5). “History of the lumber industry in the United States”, Wikipedia The Free Encyclopedia, 9 April 2021, https://en.wikipedia.org/wiki/